CarMiZa 20 A Legendary Car Audio Details Sony C1 Changer Fit Modification

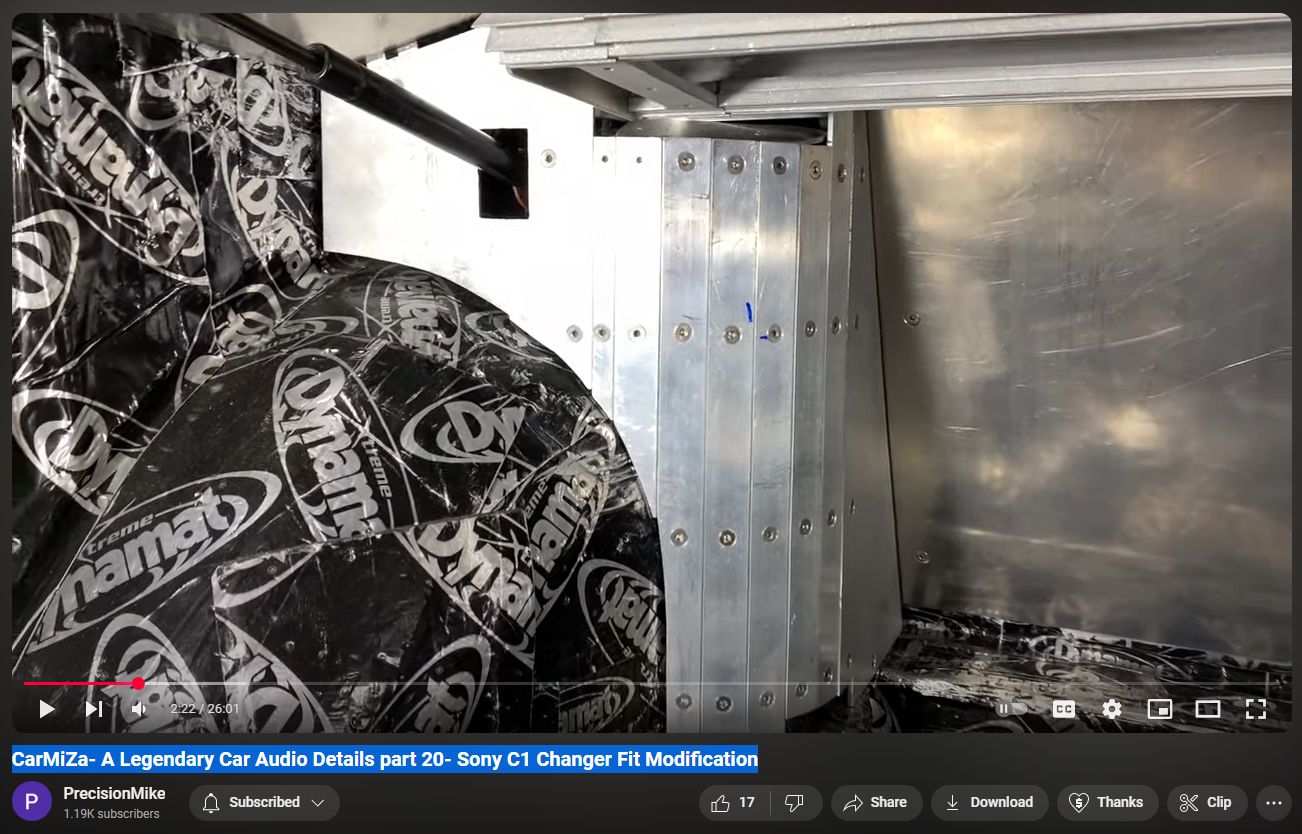

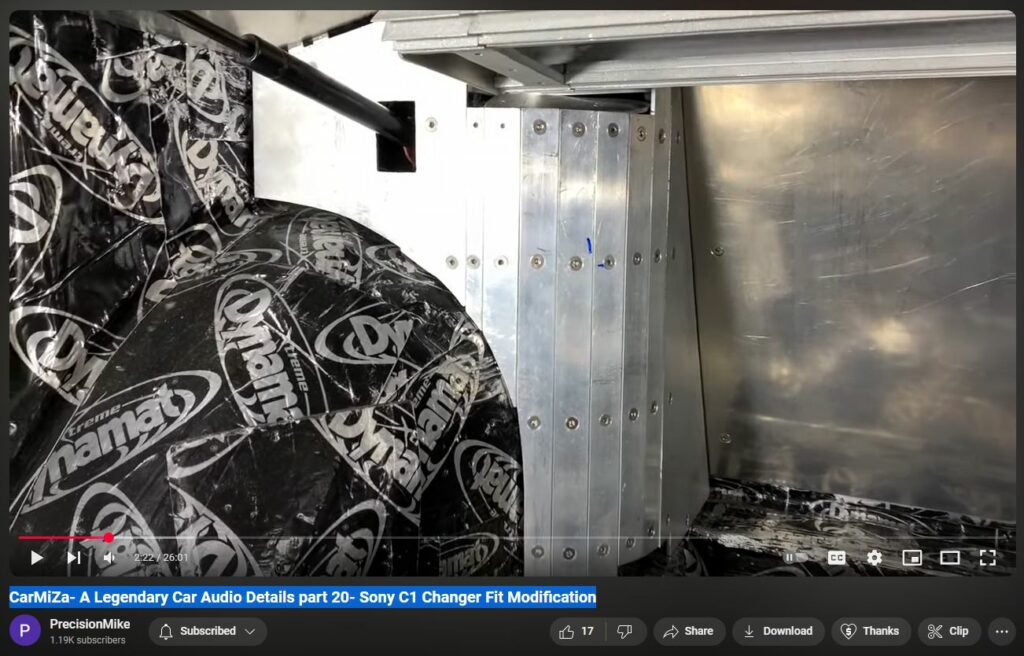

In this video, I solve a slight issue I ran into. When I built the shock tower covers, despite my best design efforts, the back of the Sony C1 changers hit the shock tower covers. As a result, I was stuck and frustrated. Here, I determine a solution and remedy the issue. Enjoy!

In the blog post titled “CarMiZa 20: A Legendary Car Audio Details Sony C1 Changer Fit Modification,” dated March 28, 2024, Michael discusses a challenge encountered during the installation of Sony C1 CD changers in CarMiZa, the rebirth of Earl Zausmer’s legendary BMW 540 audio competition car from the 1990s. The rear of the changers was obstructed by the shock tower covers, hindering proper fitment. To address this, Michael removed the back panels of the changers, each approximately an inch thick, allowing them to fit correctly. He also marked the areas on the shock tower covers where the interference occurred and considered further modifications to ensure a seamless installation. The post includes a video detailing the troubleshooting and resolution process.

Transcript

0:00

hey how's it going welcome back to Cara

0:03

this is going to be trunk details part

0:05

20 um not much progress lately with the

0:09

BMW folks I uh I can make excuses but uh

0:13

at the end of the day um I have not put

0:16

time into the car recently uh My Buddy

0:18

Joe shout out to Joe in New York uh

0:21

texted me this morning and said any

0:23

progress on the BMW and my short answer

0:25

was no so we uh I really need to roll up

0:28

my sleeves and get to work on this

0:30

um the last thing I ran into with the

0:34

install is the back of the C1 Changers

0:38

are hitting the what I'm calling the

0:40

shock Tower covers back here the

0:41

aluminum curved pieces um I had people

0:45

overs you if you're been watching the

0:47

channel uh for the expo here in town um

0:52

that Brian Schmidt put on and when

0:55

people came over I wanted them to see

0:56

the trunk so I pulled the backs of the

0:58

Changers off there was basically just a

1:00

panel that removes it's about an inch

1:02

thick and that allowed me to fit the

1:04

Changers so um as you know too I've been

1:08

talking about doing these silly side

1:10

panels forever uh I got to get on those

1:12

but in my fashion I don't go to the next

1:15

part until I've taken care of you know

1:18

done everything I can up to this point

1:19

so I certainly don't want to leave the

1:22

issue with the Changers so uh in this

1:24

video I am going to solve that I don't

1:26

know how I'm going to do it yet but this

1:28

is probably part of the reason why I've

1:31

been delayed working on it I'm stuck

1:33

right so as I mentioned with the build I

1:36

want you guys to see everything The Good

1:38

the Bad the Ugly um so this is one of

1:41

those things I have not been motivated

1:43

to work on the car um I'm loving the way

1:45

it's coming out but I'm just kind of

1:47

stuck so with that I'm going to go ahead

1:49

and remove the pull floor I'll take

1:52

these side panel bases out I'll take the

1:55

whole Milbert piece out I'll take the P1

1:58

and X1 out and just have the Changers

2:00

with the one zapco and then kind of get

2:02

an idea as to how I'm going to solve the

2:05

problem of these hitting so with that

2:07

let's go ahead and get

2:09

started okay so I've got uh everything

2:13

removed that I needed to remove and as

2:16

you can see I just took a blue Sharpie

2:18

and marked a couple of places on the

2:20

shock Tower covers where the changer was

2:23

hitting on this side I've removed the

2:25

shock Tower cover I had to pull off the

2:28

end link for the one zapco to be able to

2:30

get the cover off those those shock

2:32

Tower covers I'm thinking once I put

2:34

them in for the final time they'll be

2:36

able to come out um they're kind of a

2:38

pain but they're not going to be coming

2:40

in and out very often uh there's really

2:42

nothing that's going to be behind there

2:43

now let me show you the changer on the

2:45

bench okay so here is the changer from

2:49

the passenger side and again if you've

2:51

been following along you know that I

2:53

built uh this piece of uh 8 in aluminum

2:57

that basically acts as kind of the

2:59

bracket to hold it this changer is just

3:01

a mockup uh in fact it's

3:04

Hollow um just for weight savings and to

3:07

be able to do the mockup you can see

3:09

this one's got a pretty big scratch on

3:10

it I have uh several of these and I've

3:12

got a couple of more that are pristine

3:14

so this is the back of the changer on

3:17

these c1s these things are really heavy

3:19

duty so this is the part that's hitting

3:22

so when it's in the car it would

3:25

basically hit right here so now I got to

3:27

figure out after building this monster

3:30

right and this has got the brackets in

3:32

the back how am I going to go through

3:37

and modify this also considering the way

3:40

I'm going to upholster it um and do it

3:43

in such a way where I don't uh

3:45

jeopardize the Str structural Integrity

3:47

here but I also I need to kind of Notch

3:50

this out if you will just kind of

3:52

imagine you were just taking a a big saw

3:54

and chopping this piece out and be able

3:57

to do that without um

4:00

again you know ruining the structural

4:02

Integrity I don't want to have to redo

4:04

those straps there is a lot of drilling

4:07

there so hopefully I can figure out

4:09

something so I'm going to brainstorm and

4:12

continue working on

4:14

this okay while I work for a uh kind of

4:17

working on a solution here I also need

4:19

to make sure the changer itself was

4:21

going to fit okay with the shock Tower

4:23

itself and you can see there's it's kind

4:25

of tough to see at this angle but

4:27

there's plenty of room there's 2 or 3

4:28

Ines in between the back of the changer

4:31

and the shock Tower uh this is with the

4:33

changer cover on the back of the cover I

4:36

just have a couple of screws again it's

4:38

all machine Hardware just a couple of

4:40

screws there holding the hollow changer

4:43

in place so that part I know I'm okay

4:45

with now I have to try to figure out how

4:47

I'm going to modify the shock Tower

4:49

cover at this point I'm going to kind of

4:51

dig into this panel so what I've done if

4:53

you notice I've taken off the uh little

4:56

pocket I made for the one zapco um

5:00

and I'm going to take off these three

5:03

panels these three uh pieces of flat bar

5:05

notice I've numbered them that way I can

5:07

replicate put it all back together

5:09

without a problem I'll take those off

5:12

and then I think I may have an idea what

5:14

I'm going to do on the back side of this

5:15

strap and how I'm going to notch it so

5:17

we'll continue on okay got this piece

5:20

stripped down um and you might be

5:22

thinking too um am I kicking myself for

5:26

building this thing with all these

5:27

straps and and it took forever to build

5:30

and now I have to modify it um am I mad

5:33

at myself for the way I designed it the

5:34

answer is no because I still have the

5:37

ability to go in and modify it uh if

5:40

anything it it is in some ways easier to

5:43

do that it's not one whole complete

5:45

thing I've got to cut out and try to

5:47

notch something else back in so I'm

5:49

perfectly fine with that so um now what

5:52

I'm thinking

5:54

is I think what I'll end up doing these

5:57

two straps are the only straps in

5:59

question cuz changer only hangs down to

6:01

about the bottom of this strap so these

6:03

two are fine these I'm probably just

6:05

going to cut maybe even flush here and

6:10

then I'll run a new piece of

6:13

strap between this nut in this nut that

6:16

is curved on the back side

6:19

here and then I will take these pieces

6:24

and I will cut those this is where the

6:26

changer the bottom of the changer goes

6:27

and I'll have to allow for about a half

6:29

an inch in uh for carpet and I want to

6:31

have clearance and all that so I'll cut

6:33

all three of these like

6:36

that put them back in and then they're

6:39

going to kind of Notch in much like the

6:41

the area is for the one zap C that's

6:43

kind of what I'm thinking but uh I'm

6:45

going to play around with it and give it

6:47

some more thought and see if that's the

6:48

direction I go all right I think the

6:51

first thing I need to do is make it so

6:53

the changer fits and then worry about

6:57

rebuilding the you know the back side of

7:00

this thing so no turning back now uh as

7:02

you can see I trimmed these straps right

7:05

here here's the

7:07

offcuts right

7:09

there and this at this point the changer

7:12

should fit I'll put it back in the car

7:14

and double check what's cool is that

7:17

this thing is even with just the two

7:19

straps without the other pieces in there

7:21

it's still very very solid again call me

7:23

crazy for over engineering but um I'm

7:27

able to do the modifications I need to

7:28

do and also you know you might think

7:32

well you should have caught this you

7:34

should have seen this coming with the

7:36

Changers um as you guys know if you've

7:38

been following along I do everything I

7:40

can to pre-plan lay things out but I

7:42

think this build um there's a whole

7:44

bunch of things in this in this area of

7:46

the car it's very sophisticated and it

7:48

would have been really difficult to see

7:50

this coming so I'm not too worried about

7:51

it I'll get it fixed so all right let's

7:53

continue on sorry one other quick thing

7:56

um I know I like showing the work on I

7:58

didn't show with this but I'm really

8:00

eager to come up with a solution here so

8:02

when to do the other side I'll show you

8:03

the work I just Ed a jigsaw uh to cut

8:06

this to to trim these four Cuts uh

8:09

without taking anything apart so it was

8:11

pretty easy all right let's continue on

8:13

all right the changer fits uh the back

8:16

is on the changer as you can

8:18

see

8:20

and I got it to fit uh now I have to

8:23

fabricate you know again modify the rest

8:26

of it to to fit in there if you notice

8:29

from

8:30

the this panel to here the Gap right

8:33

there is a half an inch but here it's a

8:35

little bit bigger so what I'll do is

8:38

when I take these pieces and cut them I

8:41

want to cut them so that there's a/ inch

8:43

between the bottom of the changer and

8:45

the top of these three pieces but this

8:47

one I'll actually slice so I have a

8:49

consistent half inch Gap all the way

8:51

around so that when that's all done in

8:54

upholstered um there's the carpet's

8:56

roughly you know an e/ or so to a

8:58

quarter so so I have a a small but um

9:02

nice consistent G there um one of the

9:04

other things I've considered too on the

9:07

Changers on either side of the changer

9:09

there is on one side it's Optical and

9:11

the other side it's the unilink so I

9:14

need to integrate um getting the cable

9:17

into the side of the changer as well so

9:19

that'll be part of this kind of a

9:20

reconstructive design but um feeling

9:23

good about this is the first step is get

9:24

it to fit now I need to make it look

9:26

pretty so all right let's continue on

9:30

shock Tower cover is back out of the car

9:33

I marked this represents the bottom of

9:35

the changer and again I want a half inch

9:37

Gap so I measured a/2 in there and then

9:40

I'm going to take my three

9:42

pieces and I've already done this on

9:46

this one uh put it in place where it was

9:49

previously and Mark it and then I'll do

9:52

the same for the other two and again on

9:54

this one I'm going to slice it and then

9:57

that should get this piece kind of

9:58

restored back into place all right I

10:01

trimmed this with a jigsaw and again

10:04

even taken the care to make sure it is

10:06

very Square so now this this is number

10:09

one I'll go ahead and bu this one back

10:11

into place and again I'll bring you

10:13

along for the cuts on the driver side

10:16

okay all three pieces are trimmed and I

10:19

realized uh when I real you know uh

10:22

determine how much I needed to trim off

10:24

this one I'm going to go through the old

10:26

holes so that's not good enough it's not

10:28

precision I could do better so I'm going

10:31

to put this in the car mock it up and

10:33

just make sure my clearances are good

10:35

and everything is good I thought about

10:37

that as I was cutting this I said well

10:39

you're going to see these cut you know

10:40

the the old holes I'm going to put it in

10:43

the car do a final mockup as far as this

10:46

you know this area goes make sure that

10:49

looks good and then I'll uh cut a new

10:51

piece of aluminum I don't have any more

10:53

1 in um I thought I had more but uh I

10:57

bought about a mile of it but apparently

10:59

obviously I've used it so I'll go back

11:00

to Home Depot and get more so let's get

11:03

it in the car see how it fits okay it's

11:06

the next day I went to Home Depot got

11:08

more aluminum um and at this point let's

11:11

see if I can slide over here you can see

11:13

I just put a little clamp in here just

11:14

to be safe because I can't I don't have

11:16

the uh end cap for the one zapco to

11:19

screw into um but you can see the Gap

11:22

with that rough cut piece that I'm going

11:24

to replace looks good I got my Gap

11:26

underneath looks good and a gap behind

11:29

looks good as well so that all looks

11:31

good so at this point I will replace

11:34

piece number three I'll go ahead and get

11:36

that cut and then do the same slice and

11:38

then get it mounted in there uh and then

11:40

go to the next step all right piece

11:42

number three has been replaced with

11:44

piece number 3A and as you can see no

11:47

holes here so I just uh replicated this

11:51

and fabricated this piece again when I

11:53

do the other side I'll bring you along

11:54

for uh the cuts and things like that so

11:58

now um I'm confident that this Gap my

12:01

gaps are going to be good here now I've

12:03

got to figure out how I'm going to do

12:04

kind of a pocket in here and then what's

12:06

going to happen with this piece this was

12:08

the top pocket piece that I made for the

12:11

one zap code as you can see I removed

12:14

the cleat where this was was catching

12:17

right so I've got to figure out now what

12:19

I'm going to have to do to modify this

12:21

piece um and kind of see how the whole

12:23

thing fits together and then again

12:25

fitting in something here to build kind

12:28

of a pock for my uphol stre so I'll give

12:31

this some thought and let's see what I

12:33

come up

12:34

with the one zapco pocket is now back

12:38

into the uh shock Tower cover um I've

12:41

removed this bracket um I'm still going

12:43

to figure out what I'm going to do there

12:46

uh but now I'm going to put this back in

12:47

the car just cuz I don't want to take

12:49

anything for granted at this point make

12:50

sure everything looks good it fits and

12:52

then the last piece of the puzzle is

12:53

going to be figuring out how I'm going

12:54

to fabricate this area here um I have

12:58

some ideas but Let's uh get it in the

13:00

car make sure it all looks good and

13:01

we'll go from there okay got the piece

13:05

back in the car I put the end Link in

13:07

for the one zap go just have one bolt

13:08

holding it in place and then I've got

13:10

the changer in there as well and now you

13:13

can see it's not the exact same Gap here

13:16

and here uh it's within a 16th or

13:19

whatever but that is good I I want to be

13:22

able to maintain as much of the shock

13:25

Tower cover as possible it look like it

13:27

was intentionally notched out for these

13:28

pie pces back behind the changer what

13:31

I'm actually thinking

13:33

is at least for now I'll give it some

13:36

more thought and I know I'm all about

13:37

you know don't go to the next spot until

13:39

the next thing until the current thing

13:41

is as good as I can get it it's not a

13:43

question of it being good or not but I'm

13:45

thinking that I'm going to just leave it

13:48

with nothing back there when I upholster

13:50

this I will put carpet over the entire

13:53

piece and then I will steam it and take

13:56

pressure and basically push the carpet

13:58

if ly stretching the carpet back in that

14:01

corner the changer goes into that area

14:04

by 38 of an inch so I don't have to do

14:07

much and I think I can um basically just

14:11

get the carpet in there without any

14:12

issue so that's going to be the plan all

14:15

right got the piece back out now I'm

14:17

looking at when it was in there it was

14:19

kind of tough I was just holding things

14:20

and all that and this I'm going to leave

14:24

this piece in and these brackets these

14:25

brackets actually really strengthen the

14:27

whole thing up especially because I cut

14:29

these two so the thing is again it's

14:31

still super solid um but now what I'm

14:34

going to do is the back of the changer

14:37

comes a little bit closer than I want to

14:38

this area so I'll trim this this was

14:42

where the screw went for the bracket

14:44

somewhere around here here's a bracket

14:46

it was a right angle bracket that went

14:49

in like this just a little piece of

14:52

galvanized uh Plumbing strap and that

14:55

basically held it to here so what I'm

14:57

going to do instead is I'll still reuse

14:59

this hole and I'll put another hole

15:02

right here and I'll just do a bracket to

15:04

this back side so then that this is

15:06

still going to be very very solid and

15:08

the whole thing should be good so I'll

15:10

go ahead and do that now and then do the

15:12

final fitment and then should be go good

15:15

at that point to go to the next

15:17

side all right holy cow all right so I

15:20

trimmed this I added a little cleat just

15:23

out of that galvanized back strap back

15:26

here that keeps this really nice and

15:29

solid and then I also this was a little

15:31

bit flimsy here um so I added a little

15:34

cleat with a kind of an offset back

15:37

there you can see that again just using

15:40

that uh galvanized steel strap so now

15:42

the whole thing is back to being super

15:44

solid and I've got it notched out for

15:46

the changer so that is that side done

15:49

I'm going to put it in the car do one

15:51

last dry run of everything with the one

15:53

zap go link the changer um get in there

15:56

and make sure everything looks good with

15:58

the spacing of that especially up in

16:00

this corner that was a little bit wonky

16:02

but I think since I trim this will be

16:04

good and then from there be able to move

16:06

on to the other side hey how's it going

16:09

it is Mike um on the shock Tower covers

16:14

I am going to get this passenger side in

16:18

put all the parts in and uh show you

16:20

what that looks like and make sure it's

16:22

100% I am going to I I know I talked

16:25

about walking you through all the

16:27

changes um on the driver side shock

16:29

Tower to show you everything it's

16:31

basically the same kind of work that I

16:33

did when I initially built those so

16:35

there's really nothing crazy there and

16:36

it takes me a bit longer to do the work

16:39

when I am filming so I will knock that

16:41

out and then before this video is

16:43

concluded I'll show you both sides and

16:45

we'll be able to check the box and say

16:47

okay shock Tower covers are done

16:49

Changers fit everything is really good

16:51

then that'll wrap this video up and then

16:54

the next video is going to be finally

16:57

these side panels I really am looking

16:58

for to getting these things uh

17:00

especially being able to get them to

17:01

where like the fleece is on them I've

17:03

got the skeleton built we'll put the

17:05

fleece on and then as my buddy Joe said

17:08

start slinging some fiberglass and get

17:10

these things done and then from there

17:12

that the trunk is trimmed out then it's

17:14

going to be a matter of going back

17:15

through things and going into more

17:17

detail where I'll be doing like

17:19

paintings zapco and things like that so

17:22

all right so with that let me go ahead

17:23

and get this uh passenger uh shock Tower

17:27

cover installed with all parts and let's

17:29

take a look and make sure it is

17:32

100% okay passenger side is back

17:35

together and again see the Gap that I

17:37

have there kind of going down here

17:39

trying to keep

17:40

it pretty consistent when the carpet is

17:43

in there again I'm just going to push

17:46

the carpet in as much as I have to to be

17:48

able to fit the changer and then the

17:50

cable will come through the carpet as

17:51

well you'll see more of that when we get

17:52

to the upholstery stage um I also put

17:55

the floor in I've removed the mil BS and

17:59

all that stuff just because I want to

18:00

triple check clearances my gaps there um

18:04

I built myself a very sophisticated

18:08

gauge it's a piece of aluminum that I Ed

18:10

to double check on my gaps I want an

18:12

eighth of an inch uh so you can see the

18:14

gap between the zebrawood and the shock

18:15

Tower cover for example is exactly an

18:18

eighth of an inch on both sides um and

18:21

as I do you know I'm kind of wrestling

18:23

around with things I had that shock

18:25

Tower cover in and out 20 times probably

18:28

I want to make sure everything is still

18:29

lining up so all right so this side is

18:32

good we're 100% the back of the changer

18:35

is is on there the problem is solv so

18:37

now at this point I'm going to do the

18:39

driver's side and again I'll only record

18:41

things that are material I'm not going

18:42

to walk you through the whole process so

18:44

that I can get this knocked out and then

18:46

get over to these side panel

18:49

covers all right working on the driver's

18:51

side I just want to show this you can

18:53

see barely that line that I drew right

18:56

there on the PL number one and that is

19:01

the same exact measurement as what I

19:04

have over on this side obviously to keep

19:06

them symmetrical and before I cut it I

19:10

made that uh Mark measured it out laid

19:14

it out and then just did a visual to

19:16

make sure it's good because if you

19:17

recall that piece number one I'm not

19:19

going to use I'm going to scrap that and

19:21

I'm going to build a new piece because I

19:23

don't want to have those screw holes

19:24

visible so now I can take it out make

19:28

that piece number one and then cut the

19:30

other two pieces and I should be able to

19:32

pop it back in um put everything back in

19:34

place the one zapco end up here um the

19:39

milberg floor and just make sure

19:40

everything's 100% all my spacing is good

19:43

again if there's anything material um

19:45

that I find as I'm doing that I'll be

19:47

sure to add that to this video but uh

19:49

standby let's get this thing cut and uh

19:52

and then I'll have to put the back of

19:53

the changer on obviously that changer

19:55

has the back and that one does not so

19:58

all right let me continue on and I'll

20:00

show you what I get to all right I

20:02

figured I couldn't do a video without

20:04

showing

20:05

something um this is pretty sketchy uh

20:08

and I want to show this because you guys

20:10

always see me doing things you know

20:13

really taking my time and doing it the

20:15

proper way um and that's what I try to

20:17

do as I am Precision mic right that I

20:20

call myself so but here I need to cut

20:24

these straps I did this on the other one

20:27

and they're curved right there's no I

20:29

can't put them on a on any kind of a saw

20:31

that I own at least to be able to cut

20:33

them so I have to do it freehand with a

20:35

jigsa like this right and it's a little

20:38

bit sketchy so this would be an example

20:40

again I want to show you guys The Good

20:42

the Bad the Ugly all of that so I'm

20:44

going to go ahead and I'll cut one of

20:46

these out just to show you how I do this

20:47

again being really careful that the saw

20:50

doesn't get caught up on anything uh

20:52

that's another reason I flushed in the

20:54

hardware right so if I have to do stuff

20:55

like this I don't have a problem um and

20:58

also I'm running it at a really low

20:59

speed so let's go ahead and cut this

21:24

one all right that one is cut

21:27

through you can see right there and

21:31

that's basically I'll do the same thing

21:32

on the other side nice and slow take my

21:34

time and uh that'll be cut so uh let me

21:37

go ahead and do that and then I'll get

21:39

the other uh pie the two pieces cut that

21:41

I need to cut and then I need to make

21:43

that number one uh bar from scratch all

21:47

right I got both straps cut as you can

21:50

see there the other two and then I'll go

21:52

in with a file um and just clean up the

21:54

edge but it's quite quite a clean cut as

21:56

you can see I just used the the existing

21:59

piece of flat bar is my guide all right

22:02

let me show you at least part of this so

22:04

this is the new piece number one and as

22:07

you can see I need to cut that amount

22:10

out so once again I'm going to use the

22:12

jigsaw slow speed and I've got some WD40

22:16

on the blade I'll put a little bit more

22:18

on because I'm going to do the long cut

22:21

first and this too is pretty sketchy so

22:24

I've got

22:25

my just a workbench here and I've got a

22:28

hole cut in it this allows me to get

22:30

kind of things like this to be able to

22:32

uh get it right up to this to this Edge

22:35

like this so I me let me show you how to

22:37

do

22:55

this and that's basically

22:59

um the cool thing about this piece of

23:01

wood if you notice there's all kinds of

23:02

cuts in it I just replace the piece of

23:05

wood when it's totally shot and I don't

23:07

mind if I go into it I'd rather be safe

23:09

and not to have this hanging off the

23:11

edge like this flopping around and and

23:14

potentially the saw gets loose I'd

23:16

rather have it right up like this work

23:18

it and then I just kind of sneak it out

23:20

that way so all right let me go ahead

23:22

and get this one cut and ready to go all

23:25

right I've got the new number one piece

23:27

cut I've got my holes uh lined up and

23:31

redrilled and counter sunk and as you

23:34

can see I've got the cut made um but

23:37

it's not perfect so this I'll take a

23:39

file uh with a straight edge uh I showed

23:42

that earlier in the video and then just

23:43

clean up that edge and make sure it's

23:45

perfectly straight use my file and now

23:48

you can see that's nice and straight uh

23:50

especially when you consider there's

23:51

going to be carpet going over it that's

23:53

an eighth of an inch thick you're never

23:55

going to see any kind of flaws but again

23:57

I want to be accurate all right right uh

23:59

now I will be able to add this piece

24:01

back to the shock Tower cover and I'll

24:03

get the other two pieces trimmed okay I

24:05

got both pieces cut and again I'm going

24:07

to take a square and a file and make

24:10

sure these are perfectly

24:12

Square all right I got the back on the

24:14

changer and I've got the panel set to go

24:17

in the car so let's give it a test fit

24:19

see how it looks I do still have to

24:21

modify the pocket I'm calling it for the

24:24

one zapco which is these two pieces here

24:27

and I have to add a cleat for the number

24:29

one piece in the shock Tower cover but I

24:31

want to test fit it make sure it's all

24:33

good all right there is our Gap and

24:36

everything looks good it looks very

24:37

symmetrical compared to the other side

24:40

so now I'll pull everything back out and

24:43

um deal with the zap Co pocket and then

24:45

again I'll add a screw right on the top

24:47

of the uh number one piece that I cut

24:50

cuz otherwise it's kind of flimsy and

24:51

it'll Bend when I go to upholster

24:54

it I am officially

24:57

unstuck so everything came up great on

25:00

this side again that's the notch out on

25:04

the other side same thing you can see

25:06

the same thing there so at this point I

25:09

am done with getting the Changers to fit

25:12

that was um I don't know how many hours

25:14

of work but a decent amount of work to

25:16

get myself out of the jam that I was in

25:19

it wasn't a big deal I know I'd come up

25:20

with something but I had to just grab

25:22

some tools and get to work and start

25:24

doing it so that is going to close out

25:27

this video um I apologize for the um

25:31

delay in getting out Misa videos it's

25:34

again I'm I can make excuses but I

25:36

really need to roll my sleeves up and

25:38

get to work in the next video we are

25:40

going to uh make some progress hopefully

25:43

build these things in entirety in the

25:45

side panel so I'm pretty much sick of

25:47

hearing myself talk about it it's time

25:49

to get those going so thank you very

25:51

much for watching I certainly appreciate

25:53

it uh if you have not yet please

25:55

subscribe tell your friends and I will

25:57

see you in the next video thank you very

25:59

much take care