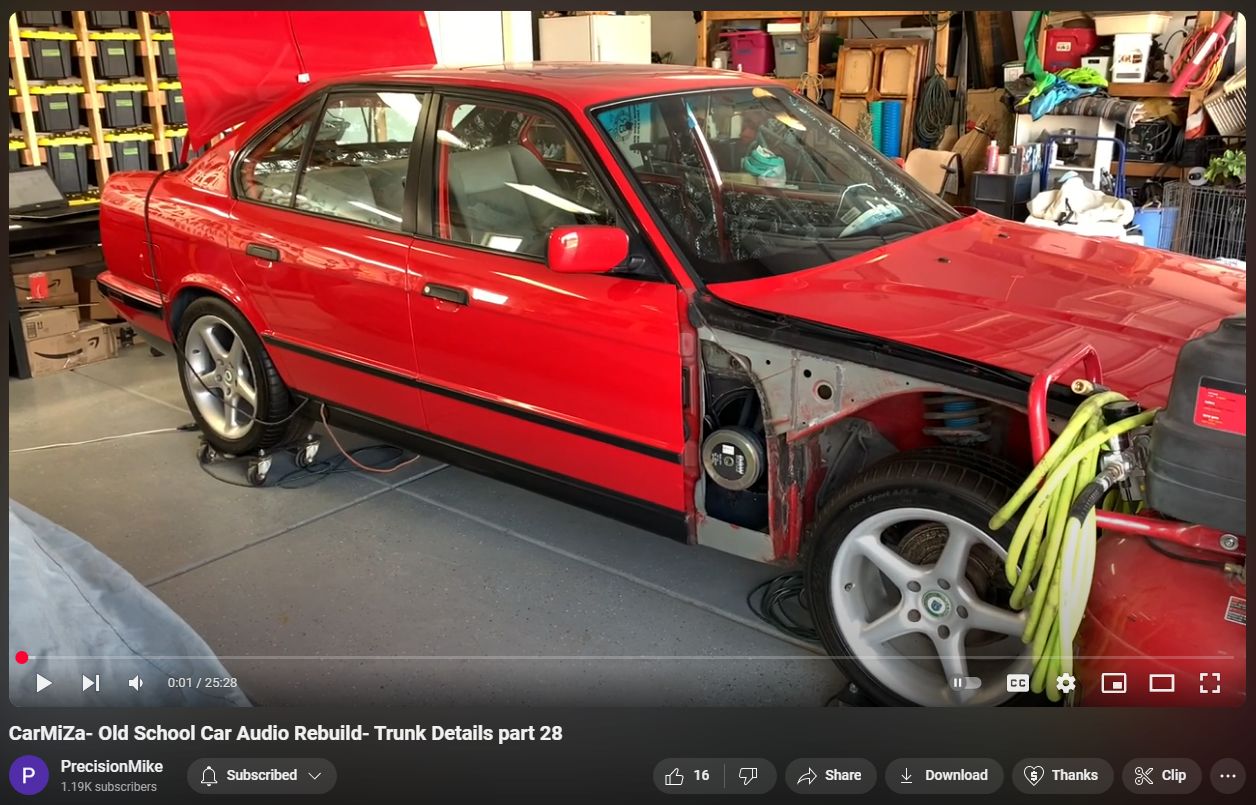

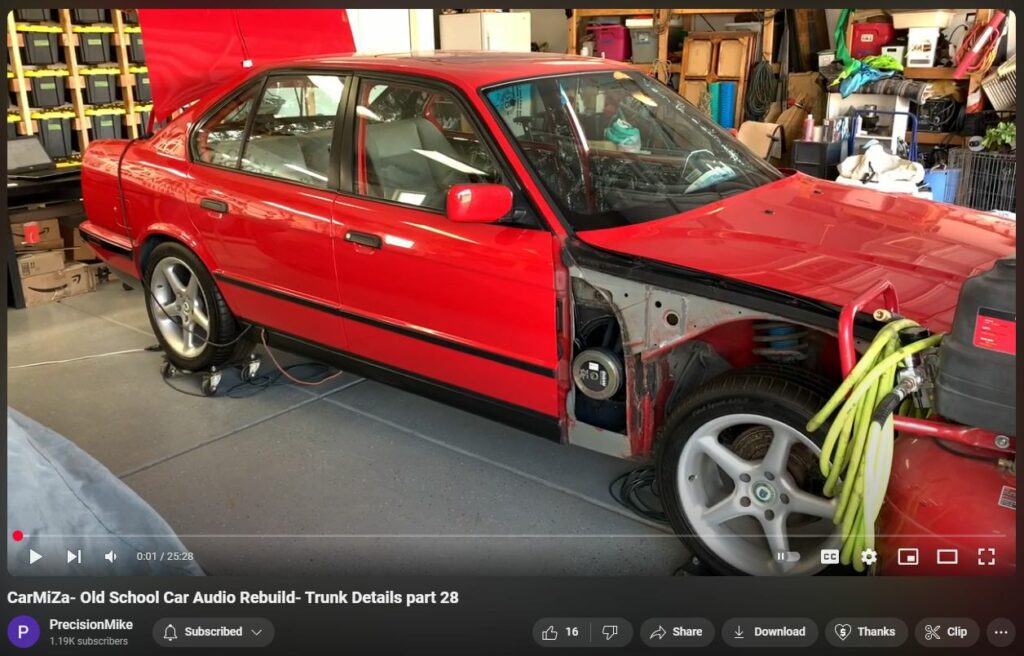

CarMiZa 28 Old School Car Audio Rebuild Trunk Details

The blog post titled “CarMiZa 28 Old School Car Audio Rebuild Trunk Details,” published on November 5, 2024, by Michael, documents the meticulous process of refining the trunk area of the CarMiZa project—a restoration of Earl Zausmer’s renowned BMW car audio system.

In this installment, Mike Michne focuses on enhancing the trunk latch area and preparing the near wall and side panels for upholstery. He emphasizes the importance of a clean appearance and addresses challenges such as exposed bolts and the integration of trunk lid bumpers. To achieve a seamless finish, Mike employs techniques like creating custom covers using ABS plastic, securing components with CA glue, and applying high-build primer to ensure a smooth surface for upholstery.

This post is part of a comprehensive series detailing the restoration of the CarMiZa BMW, which is the third iteration of Earl Zausmer’s legendary red BMW. The project is a collaboration between Mike Michne, former owner of Precision Autosound in Albany, New York, and Earl Zausmer, the original owner. The series provides in-depth insights into the challenges and solutions encountered during the rebuild, offering valuable knowledge for car audio enthusiasts and professionals alike.

“This is documented proof of explaining to customers … that installs are not an ‘overnight’ thing.”

Transcript

0:01

hey how's it going welcome back to the

0:03

channel and welcome to trunk details for

0:06

Cara uh number 28 um if you are new to

0:10

the channel uh and you may be here for

0:12

some of the other content on the other

0:13

cars I've got uh this thing is really my

0:16

main project it is a rebuild of a

0:18

legendary old school car audio system

0:20

that was owned by Earl zmer um this car

0:24

was featured in countless magazines

0:26

here's one of them um and is really

0:30

truly a legendary car when it comes to

0:31

the world of car audio so as you can see

0:34

it's got 13-in woofers in the front kick

0:37

panels uh I am very much under

0:39

construction you can see the interior is

0:41

very heavily dynamed uh the car is very

0:44

solid so check out the rest of the

0:46

channel I do have several other videos

0:48

on this car in this video we're going to

0:52

be working on the trunk uh as you might

0:54

imagine with the title and basically I'm

0:57

going to finish off this latch area and

0:59

finish off the near wall and the side

1:02

panels uh to get those prepared for

1:05

upholstery so with that let's go ahead

1:07

and get started okay so the main thing

1:10

I'm going to be doing in this video this

1:11

should be a relatively short video is

1:13

trying to clean this area up I don't

1:15

like the way it looks I don't like

1:17

obviously the exposed bolts um I did

1:19

come in here and grind down a little bit

1:21

of this I wanted to make sure that uh I

1:25

am now confident what I'm going to be

1:26

doing I needed to get it so that this

1:29

was flat across uh this will be

1:32

refinished this entire bracket we'll

1:34

talk more about that later this thing

1:36

has been driving me absolutely nuts in

1:38

terms of how to finish this off I um

1:41

sorry Earl I was driving him nuts calls

1:45

uh Facetime videos walking through how

1:47

to do this my biggest concern was making

1:49

this look clean and I also have the I'm

1:52

calling them the trunk lid bumpers I'm

1:54

sure there's a better name for them but

1:56

the adjustment tabs that basically

1:58

ensure that you've got a proper height

2:00

between the body of the car and the

2:01

trunk lid I need those and I didn't want

2:05

to have or I don't want to have it where

2:07

those things are sitting on the carpet

2:10

and they basically do an indentation

2:12

into the carpet I've seen installs with

2:14

that and to me it looks like you kind of

2:16

missed something um so later I've got a

2:20

cool idea I'll deal with that later when

2:21

I'm doing the trunk lid um this is going

2:24

to be completely redone iPad in here and

2:26

all of that but I've got a cool solution

2:28

for those later the main thing I need to

2:31

work on right now is getting these this

2:33

panel finished off and getting this area

2:35

complete so again I've got a plan and

2:37

for those of you who have been uh

2:39

following this build um again I realize

2:42

it's been quite a while since I have

2:44

shown you much content I've had a bunch

2:46

of things come up did some work on my

2:48

other cars and again if you're here for

2:50

the Mercedes content I hopefully you'll

2:52

enjoy this as well so first thing we're

2:54

going to do here is I've got a plan um

2:58

I'll go ahead and mock up what I'm going

3:00

to do I'm going to be building a cover

3:01

for this I'm going to mock it up out of

3:03

cardboard just to make sure all of my

3:05

cuts are good everything fits so let's

3:07

go ahead and dive into that all right

3:08

for mocking up I use this stuff it's

3:10

called ready board again if you're

3:12

following the channel you've probably

3:13

seen me show this before it's just a

3:15

foam uh Cuts really nice it's just over

3:18

an eighth of an inch thick and you can

3:20

get it big sheets like that that's a

3:22

full sheet uh at the dollar store for

3:24

$125 so good stuff to work with Okay got

3:27

my piece has cut um if if you're cutting

3:30

this stuff I'd suggest getting some kind

3:32

of a blade like this where you've got um

3:34

blades that you can break off and make

3:36

sure you have a really really sharp

3:37

blade that gives you a nice CR crisp

3:39

edge here um all right I've been kind of

3:41

mocking it up test fitting it in the car

3:43

at this point I'm going to go ahead and

3:45

just put a couple of very small pieces

3:47

of double-side tape on it get it mounted

3:49

in the car and then make sure my

3:50

clearance is good when I close the trunk

3:53

and this is what the two pieces look

3:55

like in the car um I did make sure I

3:57

have plenty of height here I've got I

4:00

can fit my finger in between the um

4:03

bottom side of the trunk lid and this

4:06

area so height-wise it's no problem um I

4:09

do need to verify that everything is

4:11

good in terms of clearance with this

4:12

hole I'm going to be wrapping this again

4:14

this will be made of ABS plastic I'll CA

4:17

glue it to this panel we're going to

4:19

fill it in kind of feather it out here

4:22

um sand the whole thing down and then

4:23

I'm going to hit it with a um a high

4:25

Build primer but when I upholster this

4:27

I'm going to take the carpet basic

4:29

basically cut an X in it roll my edges

4:31

over inside of this so it's just a clean

4:34

hole that's just large enough for this

4:36

latch um the latch is up there behind my

4:39

light and again at this point what I'm

4:41

going to do I'll pull my floor out um

4:44

again this is just my mockup piece

4:46

that's going to be one of the upcoming

4:47

things we're working on um and I'm going

4:50

to get inside the trunk close the trunk

4:53

with me in it and uh take a look around

4:56

here and make sure I've got just enough

4:57

of a gap I want it to be a small a hole

5:00

as possible uh but I want to ensure that

5:02

the carpet doesn't rub on the latch so

5:05

I'm going go ahead and get inside the

5:06

trunk all right um for any of you OG

5:09

people I'll be 55 in December get a

5:12

little old to be in the trunk but um all

5:15

in the name of sound quality so I took a

5:17

look at this uh it's kind of tough to

5:19

tell here I'm going to make some slight

5:22

adjustments trim one side and then we

5:24

should be good foam mockup is complete I

5:27

did have to take a little bit more off

5:28

the sides actually

5:30

um these three sides I trim down just a

5:32

little bit again getting back in and out

5:34

of the trunk just to make sure I've got

5:36

plenty of room for carpet uh plus

5:38

probably an eigh to 3/16 left over uh

5:41

just to ensure also there needs to be

5:43

some adjustment this thing is it can

5:45

adjust back and forth up and down all

5:47

that so I wanted to allow for that as

5:49

well um couple of other quick things you

5:52

might notice that um I squared off these

5:54

Corners these inside edges a lot of

5:57

times if this was going to be finished

5:58

and if I was just going to to paint this

6:00

I would round these just to give it a

6:02

softer look but when I roll the carpet

6:04

in it's kind of it'll naturally look a

6:06

bit rounded this this carpet is pretty

6:08

thick that I'm putting it it's about a

6:09

quarter of an inch thick also you might

6:11

be wondering well why didn't you just do

6:13

this out of one piece uh and bend it um

6:17

I thought about that but figured this

6:18

would be easier again I'm just going to

6:20

se glue the ABS in place and sand it and

6:23

fill it it'll kind of look curved when

6:24

I'm done all right so at this point I

6:26

can transfer this piece to the ABS

6:29

plastic

6:30

all right got my ABS plastic laid out so

6:34

um Jason if you're watching uh first off

6:37

thank you for your input on this design

6:39

as well sorry I didn't go with your idea

6:41

but hopefully you like what it looks

6:43

like in the end um I remember when I was

6:46

recently I forget what I was cutting uh

6:48

ABS 4 probably the near wall you would

6:50

mention man it looked like that uh table

6:54

saw was about to bite you with the ABS

6:56

for some reason I don't know what it is

6:58

man I get freaked out cutting ABS on a

7:00

table saw um I'd rather router 8in

7:04

aluminum so I am going to hand cut this

7:07

with a with a sharp new blade this too

7:09

I'm just thinking about it this is

7:10

something that some of you newer guys

7:12

you um modern installers if you will

7:15

probably would 3D print this or or cut

7:18

it with a you know some kind of a

7:20

automated device that you map this out

7:22

and click a button and it spits it out

7:24

but I'm going to go old school foam

7:27

templates and use a razor blade so um

7:31

I've got everything marked I'm good to

7:32

go now I'll go ahead and score this with

7:34

a razor blade cut it saying my edges as

7:37

needed and we'll be all set with that

7:40

God damn

7:42

it all right figured I'd show you what

7:45

I'm doing here when I go to score this

7:47

uh so again this is kind of an old

7:49

school way that I used to cut ABS um you

7:52

can use like a Dremel obviously or g a

7:54

table saw um but this is to me probably

8:00

I don't know the easiest and still you

8:01

get really good results so again I'm

8:03

just taking it with a um really good

8:06

sharp fresh

8:08

blade making a few scores in it this is

8:11

E8 inch ABS by the

8:13

way I'll score

8:18

it and then just break it like that

8:21

gives me a really nice crisp clean Edge

8:23

and no uh risk of taking my fingers off

8:26

in a table saw when I go to do the

8:28

inside edges that's going to be a little

8:30

bit trickier but again same principle

8:32

score it break it and pull it apart so

8:35

I'll go ahead and get this prepped one

8:37

down one to go okay got the second one

8:40

cut I'll show you this detail also um

8:43

when I cut it it gives me kind of a high

8:45

edge here just from the blade going

8:47

through uh so I'll take a sanding stick

8:50

just 60 grit or 80 grit sandpaper double

8:53

side tape to a flat piece of wood and

8:55

I'll sand it this way I've already done

8:57

it with this piece and you can see um

8:59

this whole thing again is going to be um

9:01

primered over so uh I'll get these

9:03

cleaned up and we'll get them test

9:05

fitted on the car all right here are the

9:08

pieces uh they're just sitting in there

9:10

now I'm about to double side tape them

9:12

but I also need to uh line up the

9:15

striker nothing is centered on this car

9:17

from the factory um the striker is just

9:20

slightly off center um thank you BM but

9:24

um all good so at this point I'll put my

9:26

masking tape back on Mark so that I um

9:29

where I want to be with the striker I'll

9:32

double side tape everything in place and

9:33

then I'll get back in the trunk just to

9:35

triple check uh before I see a glue

9:37

these both into place all right I did

9:40

one last test for clearance everything

9:41

looks really good so this point I'll go

9:44

ahead and see a glue these two pieces to

9:46

the near wall if you are new to the

9:49

channel when I say CA glue this is the

9:51

stuff that I use it is a two-parts

9:53

basically um a two-part superg glue

9:56

basically so um I get I like to get the

10:00

uh thick stuff uh this is somewhere

10:03

around here extra thick that's the stuff

10:06

I like to use depending on the

10:07

application so um there's different

10:10

viscosities of the actual glue itself

10:11

and then this is just a little sprayon

10:13

hardener so you apply it on uh one on

10:16

each surface and then touch the two

10:19

together once they touch they're not

10:20

going to move so get it right the first

10:21

time all right here we go all right I'll

10:23

bring you along for this part uh so next

10:25

what I'm going to do is use the CA glue

10:28

what I'm doing at this point it's just

10:30

going to tack these Pieces Just meaning

10:32

just just put enough adhesive on just to

10:35

be able to get them um stuck in place

10:40

and then I'm going to pull the panel out

10:41

of the

10:43

car at which point I will go through and

10:47

now I'm just going to spray this on

10:49

here and when I pull it out of the car I

10:52

will then Build It Up really

10:56

nice all right and again if you've never

10:59

used use this stuff it only takes a

11:00

couple of seconds to cure it's very

11:07

quick and you can't see it from this

11:09

angle but I've got my reference line for

11:12

where my Striker needs to be or the

11:15

piece needs to be relative to the

11:16

striker so got that one on that should

11:19

be good now I'll go

11:22

ahead do the same thing to the other

11:24

piece

11:29

and just a little drop I do realize too

11:32

you're going to see in a second that the

11:34

ABS plastic hangs off of the edge of the

11:37

near wall which I want I'm going to

11:39

build that up I did that kind of

11:40

intentionally or

11:42

intentionally and I want to kind of I

11:45

want it to look like it was meant to be

11:53

there all right give this just a couple

11:57

of seconds

12:00

recommend wearing gloves too because

12:01

this stuff is is nasty uh use acetone uh

12:05

to remove it if it gets on your skin

12:08

okay we'll let that cure up just a

12:10

little bit pull it out of the car and

12:12

we'll be able to continue from there all

12:15

right at this point I've got the piece

12:16

out of the car um the amount of glue I

12:18

put in was plenty to hold it in place

12:21

and now what I'm going to do is just go

12:22

around the perimeter I'll kind of show

12:24

you how I do this nothing

12:27

crazy and

12:30

I'll build up the glue

12:33

so you want to be careful not to cross

12:37

contaminate these two adhesives you

12:39

don't want to get harder on this bottle

12:43

CU that'll be kind of a mess

12:48

so an idea and it doesn't matter if I go

12:51

over and make a little bit sloppy I'm

12:53

going to do a bunch of sanding and

12:54

filling on this piece so at this point

12:57

again I've just added my glue there it

13:00

may run a little bit too all

13:04

good this is just to rough this out so

13:06

I'll do the same on the other side along

13:08

the edges make sure it's really solid

13:10

and we'll move to the next part CA glue

13:12

complete you can see I've got it on the

13:15

sides

13:16

there and we're good so everything's

13:20

nice and solid my gapping is really good

13:23

once again so now at this point I'll uh

13:26

pull it back out of the car this is a

13:27

little bit of a high spot here here so

13:29

I'll knock this down sand this down and

13:32

then we'll start to use what I call

13:34

Kitty hair it's a short strained

13:36

fiberglass reinforced body filler and

13:39

then I'm going to kind of feather this

13:41

area out we'll build this up and again

13:43

kind of make this look like it was meant

13:44

to be like it's kind of just a very very

13:47

slight kind of transition into this area

13:49

so all right let's go ahead and pull it

13:51

out of the car and we'll get that going

13:53

all right at this point I uh went ahead

13:56

and sanded this top area here uh I just

14:00

use a sanding block that same block I

14:02

showed you earlier uh just to get the

14:05

residual uh buildup from the CA glue off

14:07

of there next I'm going to build up this

14:10

area this is the product I'm using again

14:12

it's a um Bondo glass I guess you would

14:15

call it is a

14:17

manufacturer um this stuff just mixes

14:20

mixes

14:21

up I'll go ahead and add my

14:24

[Music]

14:25

hardener and I'll show you how this

14:27

works

14:29

similar to a automotive filler except

14:34

this is I think it's stronger

14:38

um and also it does a better job of

14:41

filling these larger areas

14:44

so show you this for just a

14:51

sec all right so I've got just a little

14:53

bit mixed up

14:55

here now I'll just start

14:59

building this area up just kind of

15:02

Feathering it

15:09

in with this stuff I normally mix up a

15:11

little bit less than I think I need

15:13

because it's pretty easy to waste the

15:17

material so that's kind of what I'm

15:19

looking for

15:21

there next and you have a okay wind open

15:25

time depending on um how much hardener

15:27

you mix in and how hot it is

15:29

out and the

15:39

humidity you obviously want to try to

15:42

[Music]

15:45

remove as much as you can versus sand it

15:48

I see some people just glob it on like

15:50

crazy and end up sanding you know 80% of

15:53

it away you want to try to avoid that if

15:57

possible and I tell where I'm going to

15:59

have to do probably couple two or three

16:02

applications which is fine you can

16:04

always add more anything I uh have to

16:07

sand away is just waste wasted material

16:10

time all that

16:14

so

16:16

okay we'll get this on this stuff cures

16:19

up pretty quick normally by the time you

16:21

clean up the uh your mixing plate if

16:23

you're using

16:27

one it'll harden up pretty especially to

16:29

be able to do a second application it's

16:32

pretty easy to work

16:34

with um it's pretty forgiving so I'll

16:37

continue to do this I'll build this up

16:39

until I get it to where I want start

16:41

sanding it and then ultimately uh make

16:44

the total shape so I'll keep working

16:46

away and I'll report back here in just a

16:47

moment all right making progress filling

16:49

and sanding I just want to show one

16:51

little kind of a cool detail I probably

16:52

should have shown you this before I had

16:54

a gap right in here of about an eighth

16:56

of an inch on this area here so there

17:00

was a a gap between the ABS and this

17:03

panel of about an eigh of an inch so

17:06

instead of I didn't have to you know I

17:08

didn't want to cut a piece of abs and

17:10

all that I just put a piece of tape in

17:12

here taped it from this backside and

17:15

then added the kitty hair into this side

17:17

and I ended up with a really nice proper

17:19

fill in this will harden up really good

17:22

and it looks uh finished so um this is

17:25

where I'm at so far you can see where're

17:28

kind of build this up to

17:31

transition and that's what I'm looking

17:33

for just a really subtle little Ridge

17:35

there so I'll continue to build this

17:37

shape it you can see my low spots there

17:40

um and keep going on it all right just a

17:44

quick check in making progress uh if you

17:47

notice too I'm switching between I use

17:50

uh metal and rubber uh scrapers they

17:54

both give you a slightly different kind

17:55

of an effect now when I've got these low

17:58

spots like this uh I'll go through and

18:00

use the hard scraper just to be able to

18:03

get the uh rest of the mud into that

18:05

area uh same on that side um and also

18:10

one other little Pro tip if you're doing

18:12

this or doing like finish work with like

18:14

Bondo or whatever I use compressed air

18:17

to really blow the dust off after I sand

18:20

really good and then I'll even take a

18:22

spray bottle and some water and just wet

18:24

the area and get it out of the way so

18:26

that I've got a nice clean surface for

18:28

the next coat to go on otherwise

18:30

sometimes it doesn't stick very well and

18:32

you go to sand it it just kind of peels

18:33

off so making good progress liking it so

18:36

far and uh I'll keep moving along here

18:39

all right trunk latch cover basically

18:43

complete um I will be carpeting inside

18:46

of there you can still see just on the

18:48

edges here the um bolts that hold in

18:52

this uh latch so that'll all be carpeted

18:56

inside there and then again my carpet

18:58

will come over here roll over notice

19:00

where I've got just a very slight kind

19:02

of a transition that's what I was after

19:04

just again to make it look like it was

19:07

intentional as if BMW made it um notice

19:10

too I sanded the rest of these um I did

19:13

some rattle can primer on these side

19:15

panels and on the near wall and didn't

19:18

look that great I'm not obviously this

19:20

is going to be carpeted but it's going

19:22

to driving me crazy so the next thing

19:24

I'm going to do is pull out the side

19:27

panels resand those and I'm going to

19:29

spray all three pieces with some buildup

19:32

primer and then I'm going to do a mockup

19:34

of uh my last idea uh the last piece of

19:38

the puzzle for these side panels I'll

19:40

show you that at the very end of the

19:41

video so um the other thing too in case

19:43

you've been checking this I've got kind

19:46

of an undone area up here in the corners

19:48

on both sides and that is intentional I

19:51

might be doing some lighting up there so

19:54

I'm going to leave that kind of opened

19:56

up for now uh but we'll see how that

19:59

goes after I test all the rest of my

20:01

liting so all right at this point I'm

20:03

going to wrap it up for tonight and then

20:06

tomorrow I'll pull the milts out pull

20:07

the floor out side panels get everything

20:10

out we'll sand it I'll show you how I do

20:12

the um the highb Build primer and we'll

20:15

get these things

20:17

Reed all right it's the next evening uh

20:21

dark out as you can see I am out in my

20:24

driveway and I've got the side panels

20:26

out I did a little bit more sanding and

20:29

um prepping on these got them all ready

20:33

to go uh taped off the brackets that I

20:35

built and then here I've got the near

20:38

wall all sanded prepped wiped down and

20:41

ready to go so at this point I'm going

20:43

to go ahead and get the primer gone and

20:46

I'll show you what I'm doing here okay

20:48

this is the product I'm using I realized

20:50

I got primer all over the can the label

20:52

so you can't read it but it's uh speed

20:54

coat is the brand available on Amazon

20:56

it's think it's about $100 a gallon this

20:58

is a high build

21:00

two-part um primer which is what I

21:03

should have used the first time I used

21:05

some rattle cam primer and it was junk

21:07

uh super thin this will put on a nice

21:09

relatively thick coat um and kind of

21:12

candy coat uh those three pieces so this

21:15

is the gun I use super cheap this is

21:18

like 10 bucks at Harbor Freight I think

21:20

it's more money for the regulator in the

21:23

um that's a moisture evaporator device

21:26

right there so uh I'll mix it up put it

21:29

into the gun and then hopefully I can

21:31

get a little footage where you can see

21:33

uh me actually spraying this on

22:24

all right it's a few days later and I've

22:27

got the piece is primed now what I'm

22:29

going to do is just go through knock

22:31

them down with a little bit of 60 grit

22:33

uh which I think will help uh when

22:35

they're scuffed up that'll help also

22:36

with the glue for the upholstery so I'll

22:39

get all three pieces sanded and show you

22:41

what those look like in just a few

22:43

minutes and here is everything back in

22:45

the trunk all the panels obviously I

22:47

don't have the Milbert sitting in there

22:49

um but I wanted to get an idea make sure

22:51

everything looked good with the side

22:54

panels my seams again up here I'll I'm

22:58

considering doing lighting if I don't do

23:00

lighting I'm going to close up that area

23:02

but you can see my gaps are still good

23:05

gaps are nice and consistent every time

23:07

I put everything back together that is

23:09

what the um latch are is going to look

23:13

like and then again the carpet's going

23:15

to roll inside of that and there'll be

23:16

all carpet the inside of it as well so

23:18

it'll all be very finished you won't see

23:20

any of the mounting hardware that'll be

23:22

covered up as well uh and that is it so

23:27

with this video there one other little

23:29

thing I want to show you kind of an idea

23:31

I have so give me just a couple of

23:33

minutes I'm going to set that up see

23:34

what it looks

23:35

like all right uh work with me here use

23:38

your imagination Earl had a cool

23:41

idea um of doing zebra wood on the side

23:46

panels he said do a really kind of a

23:48

thin piece uh and I'm intentionally not

23:50

showing you this just yet I'm setting

23:52

this up um I thought wouldn't it be cool

23:55

to take the factory wood wood that's on

23:58

the car on the interior of the car which

24:00

is approximately 2in strips that go on

24:03

the doors and on the dash and replicate

24:05

that in the

24:06

trunk put some paper in there to kind of

24:10

see what that would look like um

24:13

obviously it's not straight it's kind of

24:15

just all over the place

24:16

but the objective is to kind of pull

24:19

your eye into where the milbert's are

24:22

and kind of break up the big side panel

24:24

so uh Earl if you're watching I'm sure

24:26

you're going to tell me no no no go much

24:29

smaller like half the size and I don't

24:31

know where they would go too do they go

24:33

all the way up to this front area and

24:37

looking at this how far back do they

24:39

come uh so again this is just

24:42

spitballing just kind of I want to be

24:44

able to have some thought on this before

24:47

um you know I'm to the point where I'm

24:49

actually upholstering so all right so

24:52

with that this is going to close out

24:54

this video so I know again it was a

24:56

short video if you made it this far

24:57

thank you very much much um in the next

25:00

video I'm going to be doing the trunk

25:02

lid cover I'm going to get literally

25:04

start working on that in about 10

25:06

minutes so I'm going to put the the

25:08

phone down stop recording this pull the

25:09

trunk lid and get to work on that I've

25:12

got some really cool ideas for that um

25:14

there's going to be some neat things

25:15

going on there so thank you very much

25:17

for watching certainly appreciate it if

25:19

you have not already please like And

25:21

subscribe and there will be much more

25:23

music content coming soon thanks very

25:25

much talk to you soon take care